The industry's first FFU replacement of old ones with new ones, energy-saving replacement, and whole-plant planning

FFU from European, American, Japanese, Taiwanese, mainland and other manufacturers’ brands can be replaced painlessly.

FFU from European, American, Japanese, Taiwanese, mainland and other manufacturers’ brands can be replaced painlessly.

- Compatible with all brands of FFUFor Gebhardt, M+W, EBM, ZIEHL-ABEGG, TLT, SINKO, FUJI, Topre Corporation, TOP WELL, KOWA, AAP, AIRTECH, DEI, etc., FFU from European, American, Japanese, Taiwanese, mainland and other factory brands can be used Painless replacement.

- Achievements Covers how companies manage their employees, working environment, information security, customers, suppliers, etc.

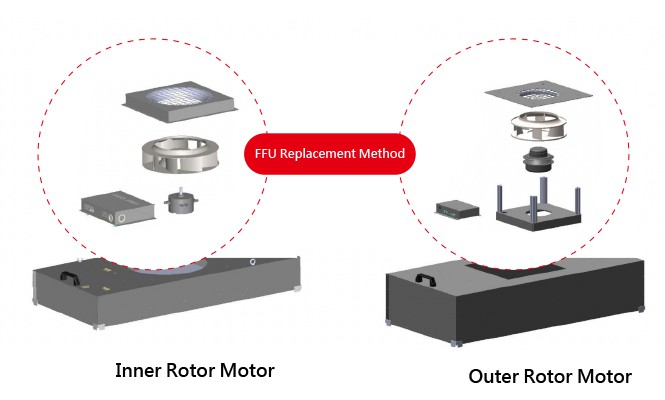

Schematic diagram of replacing old fans with new ones

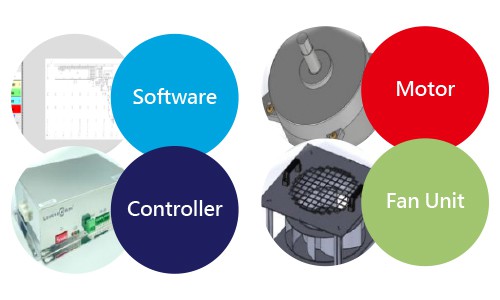

Replacement method

Keep the original box and filter

Replacement of parts that have expired, such as:

Graphic control software/hardware, controller, motor.

The original box components that will not be damaged are retained to extend the operating life of the FFU.

Maintain the original clean room environment

When replacing fan blades, motors and controllers,

Does not affect the positive pressure environment and cleanliness of the clean room.

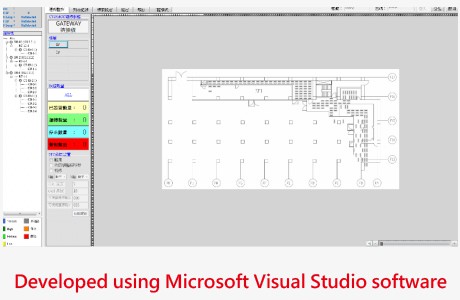

Replace FFU graphic control software/hardware

- Provide free image control software

- Compatible with Microsoft operating systems

- There is no commercially available SCADA and you need to purchase communication points and execution software

- There are no compatibility issues with new and old versions of commercially available SCADA execution software

- More than 20 permission settings

- Can provide external systems to read FFU connection information

- Can be nested into floor plans

- Provides USER with the ability to add and delete FFU independently

Replace with new FFU controller

- Replacing a new FFU controller can effectively save 8%~20% energy efficiency

- Power supply system: single-phase, three-phase

- Voltage specifications: can be customized according to needs

- Can match the size of the old FFU controller mechanism

- Compatible with old FFU power terminal specifications

- Maximum power of controller : 450W

- Comply with CE national safety certification

Replace with new FFU permanent magnet motor

- Permanent magnet motor efficiency>85%

- Bearing anti-electrical corrosion treatment

- Using permanent magnets

- Compatible with the size of the old FFU motor mechanism

- Compatible with old FFU motor power terminal specifications

- Using aluminum die-cast housing

- Compliant with IP56 waterproof rating

Replace fresh air unit

- Replacing the fresh air unit can effectively save 8%~23% energy efficiency

- There are solutions for both internal and external rotor motors

- Provide replacement fan characteristic curve (PQ)

- Compatible with the size of the old FFU controller mechanism

- Compatible with old FFU power terminal specifications